基于Arduino的PID循迹小车(改进版) |

您所在的位置:网站首页 › arduino小车循迹图形代码 › 基于Arduino的PID循迹小车(改进版) |

基于Arduino的PID循迹小车(改进版)

|

上次我们打造了一辆基于Arduino的循迹小车,并且加入了PID算法。 https://znzcqy.github.io/post/Nzx8AZmvk/ 但是小车的表现却不尽如人意,于是我对代码进行了改进,并且不再使用L298N电机的ENA,ENB使能端,对线路进行了简化,直接采用Arduino的带PMW的引脚来对小车进行速度控制。电池方面,换成可充电的锂电池(3.7V X3),以保证小车的速度。在上次的赛道中,赛道总长度大约为5.14m,要实现在7s内跑完全程的目标,就必须要更高的速度。

下面是改进后的代码 #define righA_PIN 5 #define righB_PIN 3 #define leftA_PIN 10 #define leftB_PIN 9 #define leftA_track_PIN 2 #define leftB_track_PIN 4 #define middle_track_PIN 6 #define righA_track_PIN 7 #define righB_track_PIN 8 float Kp = 15 , Ki = 0, Kd = 200; //pid弯道参数参数 float error = 0, P = 0, I = 0, D = 0, PID_value = 0;//pid直道参数 float previous_error = 0, previous_I = 0; //误差值 int sensor[5] = {0, 0, 0, 0, 0}; // //5个传感器数值的数组 static int initial_motor_speed = 200; //初始速度 void read_sensor_values(void); //读取初值 void calc_pid(void); //计算pid void motor_control(void); //电机控制 void motor_pinint( ); //引脚初始化 void setup() { Serial.begin(9600); //串口波特率115200(PC端使用) track_pinint( ); //循迹引脚初始化 motor_pinint(); //电机引脚初始化 } void loop() { read_sensor_values(); //循迹小车 calc_pid(); motor_control(); } /*循迹模块引脚初始化*/ void track_pinint( ) { pinMode (leftA_track_PIN, INPUT); //设置引脚为输入引脚 pinMode (leftB_track_PIN, INPUT); //设置引脚为输入引脚 pinMode (middle_track_PIN, INPUT);//设置引脚为输入引脚 pinMode (righA_track_PIN, INPUT); //设置引脚为输入引脚 pinMode (righB_track_PIN, INPUT); //设置引脚为输入引脚 } void motor_pinint( ) { pinMode (leftA_PIN, OUTPUT); //设置引脚为输出引脚 pinMode (leftB_PIN, OUTPUT); //设置引脚为输出引脚 pinMode (righA_PIN, OUTPUT); //设置引脚为输出引脚 pinMode (righB_PIN, OUTPUT); //设置引脚为输出引脚 } //速度设定范围(-255,255) void motorsWrite(int speedL, int speedR) { if (speedL > 0) { analogWrite(leftA_PIN, speedL); analogWrite(leftB_PIN, 0); } else { analogWrite(leftA_PIN, 0); analogWrite(leftB_PIN, -speedL); } if (speedR > 0) { analogWrite(righA_PIN, speedR); analogWrite(righB_PIN, 0); } else { analogWrite(righA_PIN, 0); analogWrite(righB_PIN, -speedR); } } void read_sensor_values() { sensor[0] = digitalRead(leftA_track_PIN); sensor[1] = digitalRead(leftB_track_PIN); sensor[2] = digitalRead(middle_track_PIN); sensor[3] = digitalRead(righA_track_PIN); sensor[4] = digitalRead(righB_track_PIN); if (sensor[0] == 0 && sensor[1] != 0 && sensor[2] != 0 && sensor[3] != 0 && sensor[4] != 0) { error = -4;//01111 } else if (sensor[0] == 0 && sensor[1] == 0 && sensor[2] != 0 && sensor[3] != 0 && sensor[4] != 0) { error = -3;//00111 } else if (sensor[1] == 0 && sensor[0] != 0 && sensor[2] != 0 && sensor[3] != 0 && sensor[4] != 0) { error = -2;//10111 } else if (sensor[1] == 0 && sensor[0] != 0 && sensor[2] == 0 && sensor[3] != 0 && sensor[4] != 0) { error = -1;//10011 } else if (sensor[2] == 0 && sensor[1] != 0 && sensor[0] != 0 && sensor[3] != 0 && sensor[4] != 0) { error = 0;//11011 } else if (sensor[3] == 0 && sensor[1] != 0 && sensor[2] == 0 && sensor[0] != 0 && sensor[4] != 0) { error = 1;//11001 } else if (sensor[3] == 0 && sensor[1] != 0 && sensor[2] != 0 && sensor[0] != 0 && sensor[4] != 0) { error = 2;//11101 } else if (sensor[4] == 0 && sensor[1] != 0 && sensor[2] != 0 && sensor[3] == 0 && sensor[0] != 0) { error = 3;//11100 } else if (sensor[4] == 0 && sensor[1] != 0 && sensor[2] != 0 && sensor[3] != 0 && sensor[0] != 0) { error = 4;//11110 } else if (sensor[0] != 0 && sensor[1] != 0 && sensor[2] != 0 && sensor[3] != 0 && sensor[4] != 0) { error = 0;//11111 } } void calc_pid() { P = error; I = I + error; D = error - previous_error; PID_value = (Kp * P) + (Ki * I) + (Kd * D); previous_error = error; } void motor_control() { int left_motor_speed ; int right_motor_speed ; left_motor_speed = initial_motor_speed + PID_value; right_motor_speed = initial_motor_speed - PID_value; if (left_motor_speed < -255) { left_motor_speed = -255; } if (left_motor_speed > 255) { left_motor_speed = 255; } if (right_motor_speed < -255) { right_motor_speed = -255; } if (right_motor_speed > 255) { right_motor_speed = 255; } motorsWrite(left_motor_speed, right_motor_speed); }最后再说明一下,PID参数需要自己调节,通常先把速度调到50,Ki,Kd先赋值为0,调节Kp,直到能循迹了,再把速度调大,调节Kd即可,Ki是积分常数,一般为0,如果小车不稳定,可以适当赋值。实测小车速度赋值为200时,跑完一圈大概5s。这时我们可以适当把速度再调高,挑战速度的极限,通常需要更换摩擦力更大的赛道地面。 |

【本文地址】

今日新闻 |

推荐新闻 |

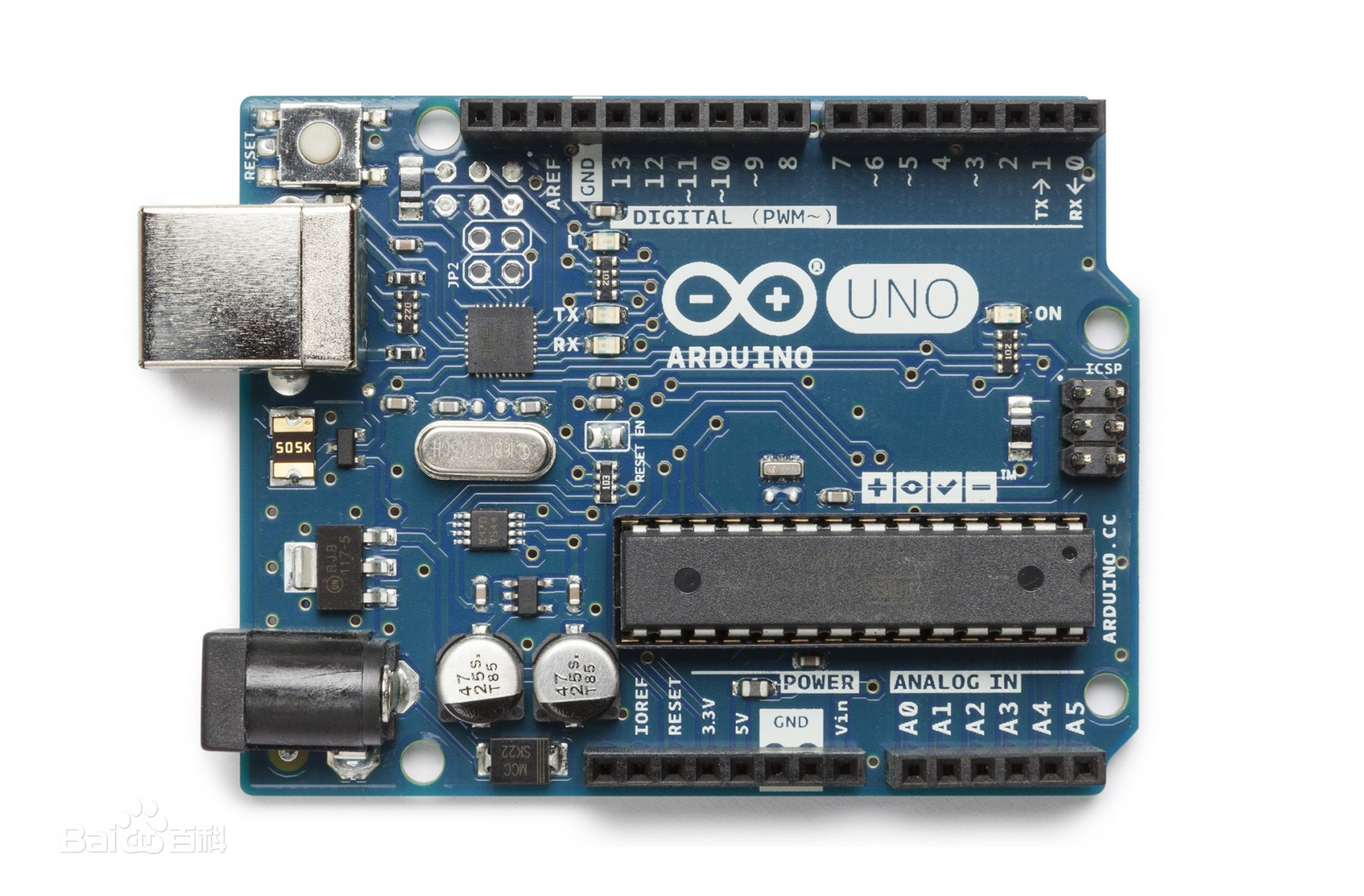

推荐使用正版arduino开发板

推荐使用正版arduino开发板